Per NFPA 20 (2010): Standard for the Installation of Stationary Pumps for Fire Protection, fire pumps are allowed to have a 40 percent rise in pressure from rated flow to churn. One thing that some engineers forget is that the pump will discharge at a much higher pressure at churn (no flow) than at the design point. However, the friction loss and pipe sizing become an issue when doing this calculation, which is why most contractors and sprinkler designers use software.

As you can see, the calculated required pump psi is 180 psi.Ī similar calculation can be used for a non-high rise, by changing the 100 psi to the end head pressure (15 – 50 psi, depending on the head).

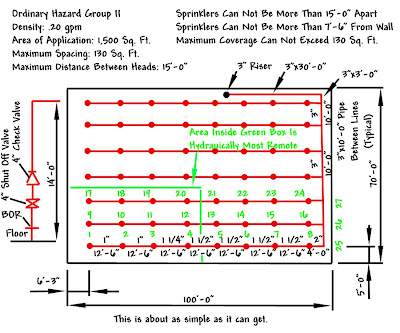

#Fire sprinkler system design for lif tny software

This discussion concentrates on high rises because the pressure calculations for most non-high-rise buildings are determined through the use of software specifically designed for fire sprinkler hydraulic calculations. This is a factor because any high rise requires a pressure of 100 pounds per square inch (psi) at the top of the structure while flowing the rated gallons per minute (gpm) of the fire pump. One is for high-rise structures (buildings greater than 75 feet in height, measured from the lowest level of fire department vehicle access to the floor of the highest occupiable story) and one is for non-high-rise structures. Two types of structure calculations for pressure are available.

In any case, the demand of the system will dictate the pressure and flow required. For standpipe systems, this flow is related to the type and size of the structure the pump is protecting. The last job parameter you need in order to size the fire pump is the required flow for the systems the pump will be serving (sprinklers, standpipes, or other). Thus, if the water supply is located below the suction inlet to the fire pump, you may have to utilize a vertical turbine fire pump in lieu of the other types of pumps available. If you are using a private water supply, lake, or ground-level storage tank, you must remember that you are not permitted to use a suction lift with a fire pump. If not, request a new test using more hydrants or plot a water supply curve (see Figure 1). Additionally, in highly residential areas, peak morning use typically occurs early in the day, between 6:30 and 9 a.m., so that may be the best time for the test.Īnother consideration regarding the water test is this: Did the city flow enough water to meet 150 percent of the fire pump design point? This will ensure that the municipal supply will provide enough volume to meet the system demand. In a cold climate, testing during the summer may be a better choice, since residents are watering their lawns and commercial properties are using more water for cooling.

Make sure the water test is performed as close to the tap point as possible.Make sure the water test is less than a year old.If you are utilizing the city water supply as the primary source for the pump, you need to make sure that an accurate city water test is used. When starting a fire pump design, the most important item to consider is the water supply.

0 kommentar(er)

0 kommentar(er)